Description

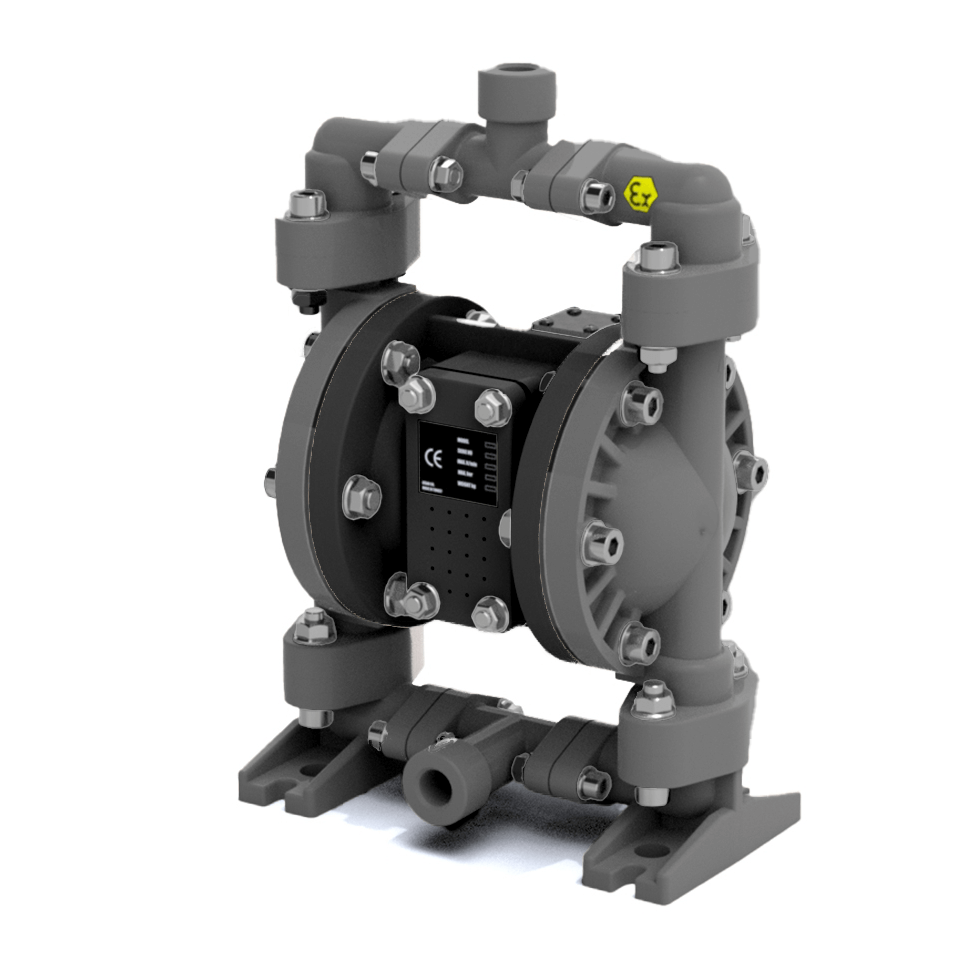

The ANT08XE-SP-5 Diaphragm Pump is an ATEX-certified solution engineered for safe and efficient fluid transfer operations in hazardous environments. Featuring a conductive polypropylene body, this pump combines durability with static dissipative properties, ensuring compliance with safety standards in explosive atmospheres. With a maximum flow rate of 18 liters per minute and a pump speed of 250 cycles per minute, it provides reliable performance, enhancing productivity and safety. The 1/4″ NPT fluid inlet-outlet size and 1/8″ air inlet size enable easy integration into existing systems, ensuring seamless operation. Operating at a maximum fluid working pressure of 8 bar, it maintains steady and reliable fluid transfer while minimizing downtime. Featuring a 1:1 ratio, it ensures precise pumping, optimizing overall performance. Constructed with conductive polypropylene for both the pump housing and center section, it offers resilience and durability in challenging operating conditions. The diaphragm and check-valve, made from TPE, ensure compatibility with various fluids and enhance durability. With a maximum suction lift of 9.5 meters when wet and 2.5 meters when dry, it offers flexibility in installation and usage. Operating at a maximum temperature of 80°C and emitting a low sound level of 61 dBa at 5 bar, it prioritizes operator comfort and safety. Weighing 1.2 kg, it combines lightweight design with robust construction, making it an ideal solution for fluid transfer challenges in hazardous environments. From chemical processing to oil and gas industries, the ANT08XE-SP-5 Diaphragm Pump stands as a reliable and efficient choice, ensuring optimal performance and compliance with safety regulations.